Underlays, sarking membranes and subroofs for pitched roof systems

Goodbye sloping roofs. The trend in modern architecture is increasingly towards flat roofs. For roof cladding, this presents a major challenge in terms of rain protection. This is because, in contrast to traditional pitched roofs, rain cannot run off due to the lack of roof slope. An intermediate architectural solution that is becoming more and more popular is the flat pitched roof.

In Germany, the standard roof pitch is specified for various tile shapes and ranges from 9° (with approval) to 40°. If the pitch is less than this, a sub-roof is mandatory. For this application, CaPlast offers particularly durable, multi-layer membrane structures with PU-coated fleeces. They are completely waterproof, extremely flexible and easy to weld.

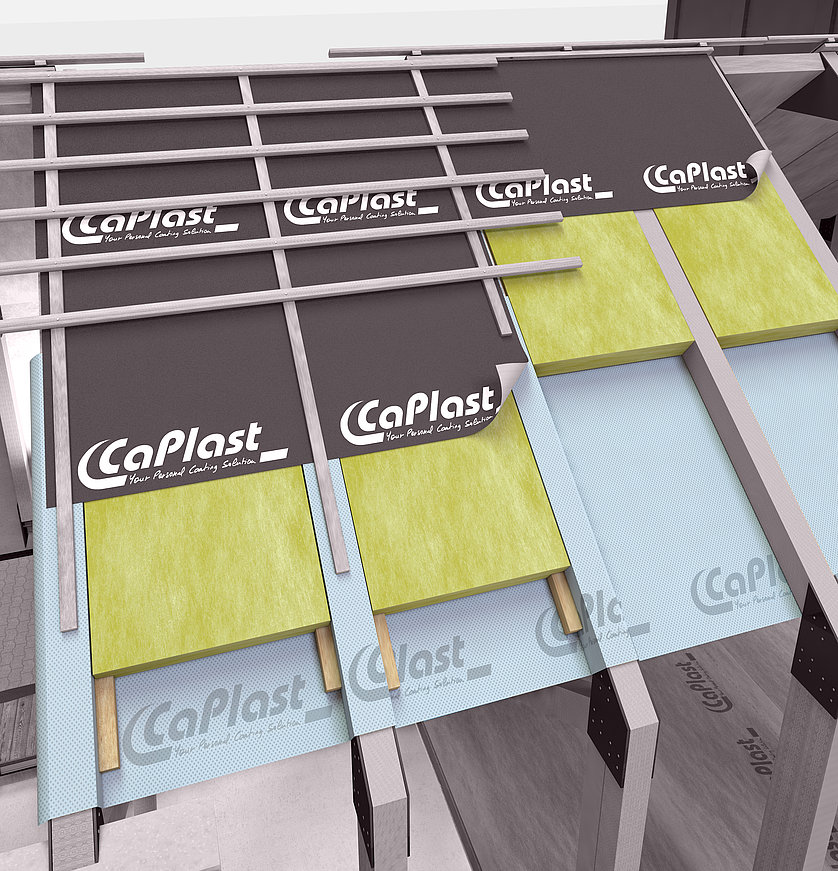

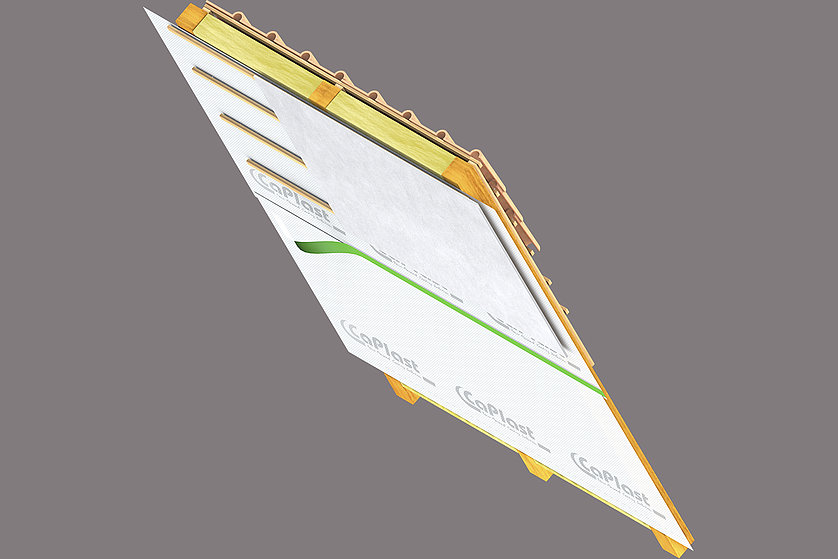

Since all roofs today are usually insulated and the attics are used as living space, the sarking membrane is the most common roofing membrane for pitched roofs with standard roof pitch. It lies directly on the insulation, so it is imperative that it be open to diffusion on the cold side so that the moisture that penetrates into the roof structure from the building is removed to the outside.

CaPlast sarking membranes can always be used as underlays as well. Underlays form the second water-bearing layer below the roof covering in undeveloped and insulated attics and are stretched slightly sagging between the rafters.

Possible applications of the waterproof CaPlast roofing membranes

- Underlay membrane (UDB) and breathable underlay membrane (USB)

- Temporary roofing/rainproof sub-roofing

- Shuttering membrane

- Ventilated and non-ventilated constructions

- Renovation and new construction

- Under-covering under PV systems or solar thermal systems

- Rainproof and watertight sub-roofing

Configure your roofing membranes individually

With CaPlast, you have the option of matching functional properties such as sd value, tear strength, tensile strength, elongation, color, outdoor weatherability, makeshift covering and temperature resistance precisely to the desired application and targeted functionality of sarking membranes, underlayments and subroofs. Talk to us about your requirements in terms of sustainability, energy efficiency, thermal insulation, transparency, handling, printing and quality. In the download area, you will find our current data sheets.

Important properties for sarking membranes, underlays and subroofs

- Temperature resistant up to 120 °C

- Long outdoor exposure times possible

- Impervious to driving rain

- Highly abrasion and scratch resistant

- Highly open to diffusion

- Flame retardant

- Installation safe

- Oil and surfactant resistant

- UV-resistant

- Heat and swell weldable

Suitable system accessories

For all CaPlast sarking and underlayment membranes, we offer the appropriate system accessories such as adhesive tapes for the overlap area of the sarking and underlayment membranes, UV-stabilized adhesive tapes, nail sealing tapes for temporary coverings, liquid plastics, adhesives and sealants, transparent and permanently UV-stable adhesive tapes, welding strips and swelling welding agents, weldable corners as well as watertight connections of pipe penetrations.

Common materials for CaPlast underlayment, sarking and subroofing

We know how to optimize the physical properties of modern roofing membranes. Our sales department will be happy to advise you on the choice of material and coating for your application.

- Application-specific combination of PP nonwovens, fabric reinforcement and functional membrane

- Multilayer structure of polyurethane functional layers and PES nonwovens

- PES nonwovens with polyurethane coating

- Mesh reinforcement laminated with insulating fleece