Vapor retarders and vapor barriers for pitched roof systems

A 4-person household produces around 10 liters of water vapor per day. In highly thermal insulated low-energy and passive houses, this moisture can no longer escape. The air quality decreases, and the water vapor can settle as condensation in the layers of the building envelope. Opening the windows for ventilation is counterproductive, because the heat escapes and the energy-saving effect is lost.

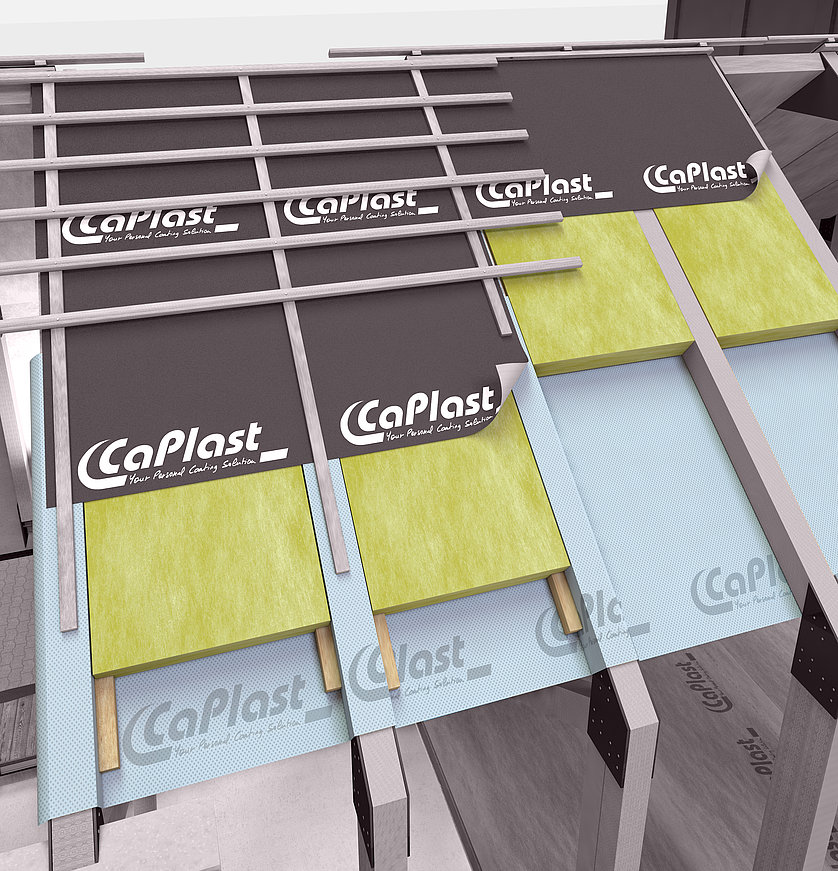

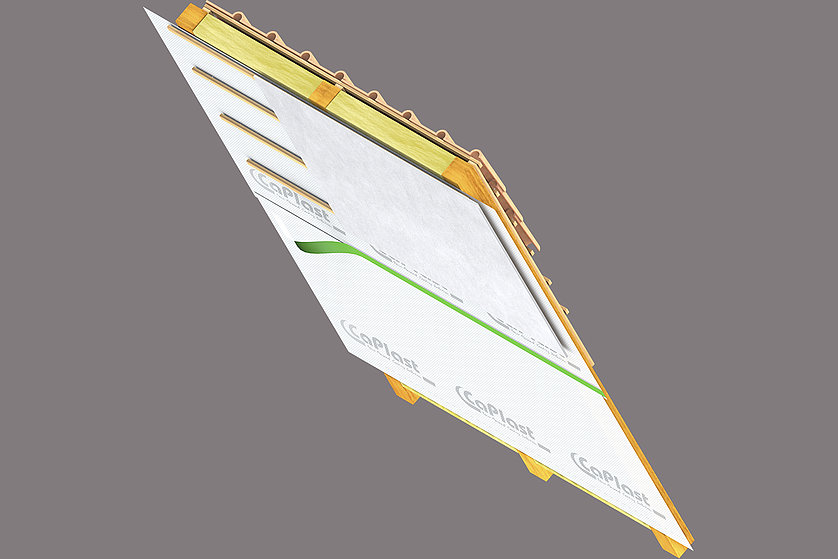

A remedy for pitched roofs is vapor retarders, which are applied to the full surface of the warm side of the thermal insulation layer on the inside. According to EnEv, they must be airtight, but are permeable to water vapor on both sides. Special material properties allow the diffusion of water vapor from the warm to the lower temperature and from the higher to the lower pressure.

Vapor retarders with an sd value up to a maximum of 1500 m are the norm today. Only diffusion-tight vapor barriers with an sd value of more than 1500 m are used for special applications, because the barrier layer prevents regular moisture equalization, which can lead to damage to the building fabric in the long term.

Possible applications of CaPlast vapor retarders and vapor barriers

- Vapor retarder for interior finishing

- Vapor retarder for on-roof insulation

- With and without formwork

- Flat pitched roofs such as industrial halls etc.

- Suitable for trapezoidal sheet metal substrates

- Suitable for mechanical fixation and under ballast

- Unventilated, diffusion-open wall and roof constructions

- Wooden post and beam construction

- Ventilated and non-ventilated systems

- Suitable for blow-in insulation

You will find our current data sheets in the download area.

Configure your vapor retarders individually

With CaPlast, you have the option of matching functional properties such as sd value, tear strength, tensile strength, elongation, color and structures precisely to the desired application and the target functionality of the vapor retarder or vapor barrier. about your requirements in terms of sustainability, energy efficiency, thermal insulation, transparency, handling, printing and quality. In the download area you will find our current data sheets.

Important properties for vapor retarders and vapor barriers

- Impervious to driving rain

- Highly loadable

- High tear strength, nail pull-out resistant, perforation resistant

- sd values from 2 to > 1500

- Self-adhesive strips on all sides (also double-sided)

- Inherently stable

- Translucent (rafters visible)

- Alkali-resistant

- Ecological

- Increased thermal insulation / radiation barrier

- Heat reflective

- Energy efficient

Suitable system accessories

For all vapor retarders and vapor barriers from CaVap, we offer you the right system accessories such as prefabricated corners, permanently elastic adhesives and sealants, adhesive tapes for interior and exterior bonding, for bonding vapor retarders, for repairs or for the air-, wind- and watertight connection of overlaps and penetrations.

Common materials for CaPlast vapor retarders and vapor barriers

We know how to optimize the physical properties of modern vapor retarders. Our sales department will be happy to advise you on the selection of material and coating for your application.

- Copolymer-coated PP nonwoven

- Lattice-reinforced, aluminum-vaporized PE film

- Multi-layer, mesh-reinforced composite of soda kraft paper with air moisture regulating functional layer

- Fabric-reinforced polyolefin coating with insulating fleece

- Multilayer aluminum composite with fabric reinforcement