Vapor retarders for flat roofs

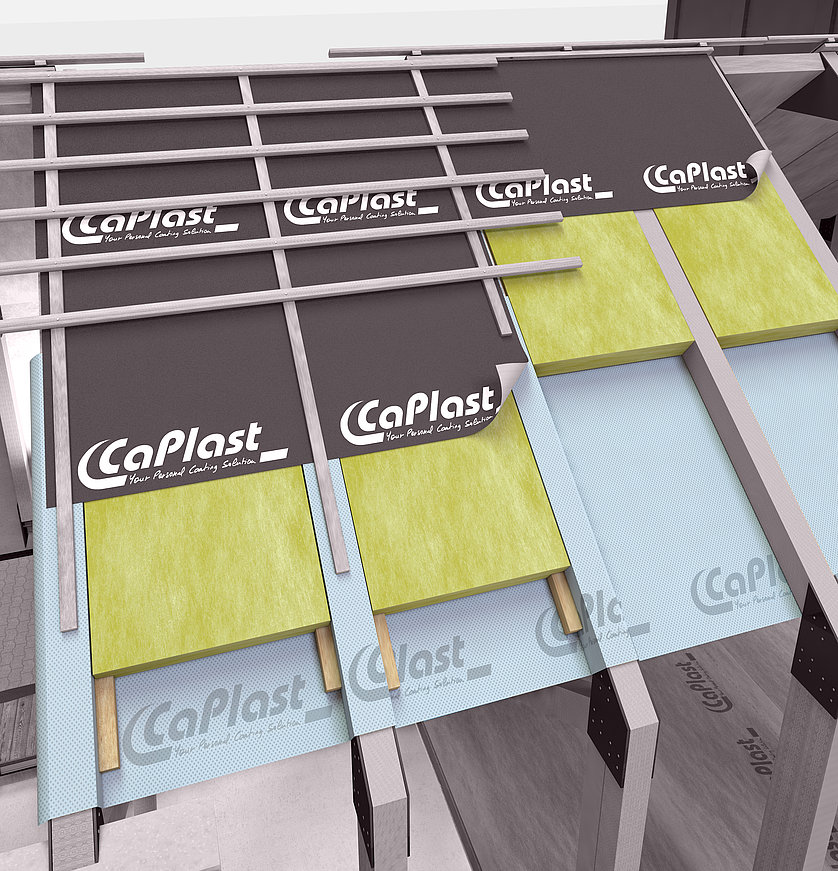

When constructing flat roofs, there are two main requirements from the relevant codes and standards: Rain protection and fire protection. Since the top layer of a flat roof must be absolutely watertight and rainproof, condensation water cannot diffuse in or out. For this reason, additional measures must be taken to prevent moisture from penetrating into the roof structure from the inside, especially into the insulation.

In practice, vapor barriers with an sd value of more than 1500 m made of plastic foil, bitumen foil or aluminum composite foil are used.

In the case of large roof areas (more than 2,500 m2 according to DIN 18234), fire propagation via the roof must also be retarded. The fire load of vapor barriers designed according to standards must not exceed 10,500 kJ/m2 and they must be at least normally flammable (building material class E according to DIN EN 13505-1).

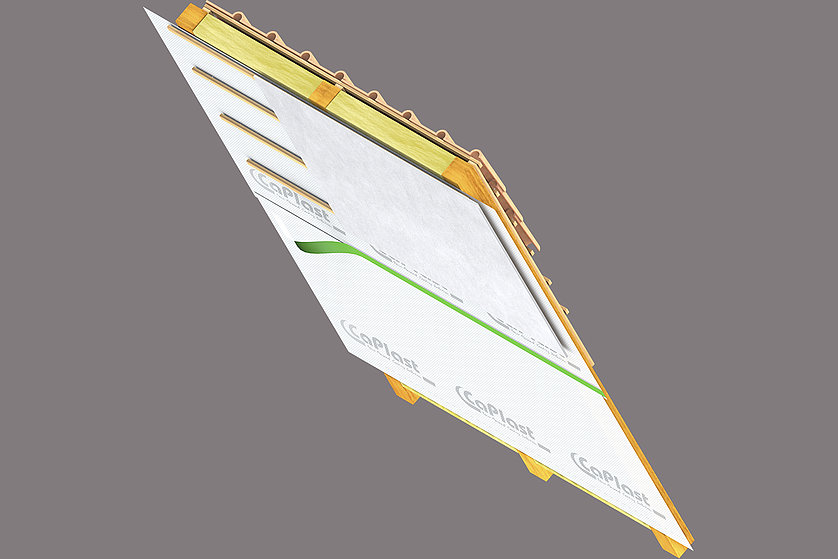

For this application, CaPlast offers diffusion-tight air and vapor barriers made of multilayer aluminum composite with extremely tear-resistant fabric reinforcement, which are laid between the reinforced concrete ceiling or trapezoidal profile and thermal insulation. For easier installation, we equip the sheets with a self-adhesive layer on the underside on request.

We will be happy to assist you in testing your complete systems for flat roof construction for compatibility with our CaVap Alu vapor retarders.

Configure your vapor retarders individually

At CaPlast, you have the option of matching functional properties such as sd value, tear strength, tensile strength, elongation, flame retardancy, outdoor weatherability, and temperature resistance precisely to the desired application and target functionality of vapor retardants. Talk to us about your requirements in terms of sustainability, energy efficiency, thermal insulation, transparency, handling, printing and quality. In the download area you will find our current data sheets.

Important properties of vapor barriers for the flat roof

- Self-adhesive over the entire surface

- Highly abrasion and scratch resistant

- Highly open to diffusion

- Screw-through resistant

- Flame retardant (burning dripping) according to DIN 4102/B1

- Installation safe

- Oil and surfactant resistant

- UV-resistant

- Heat and swell weldable

Common materials for CaPlast vapor barriers

We know how to optimize the physical properties of modern vapor barriers. Our sales department will be happy to advise you on the selection of material and coating for your application.

- multilayer aluminum composite with tear-resistant fabric reinforcement

- optionally with full-surface acrylate or hotmelt adhesive plus liner for protection